Warehouse Inventory Management

Inventory Proline

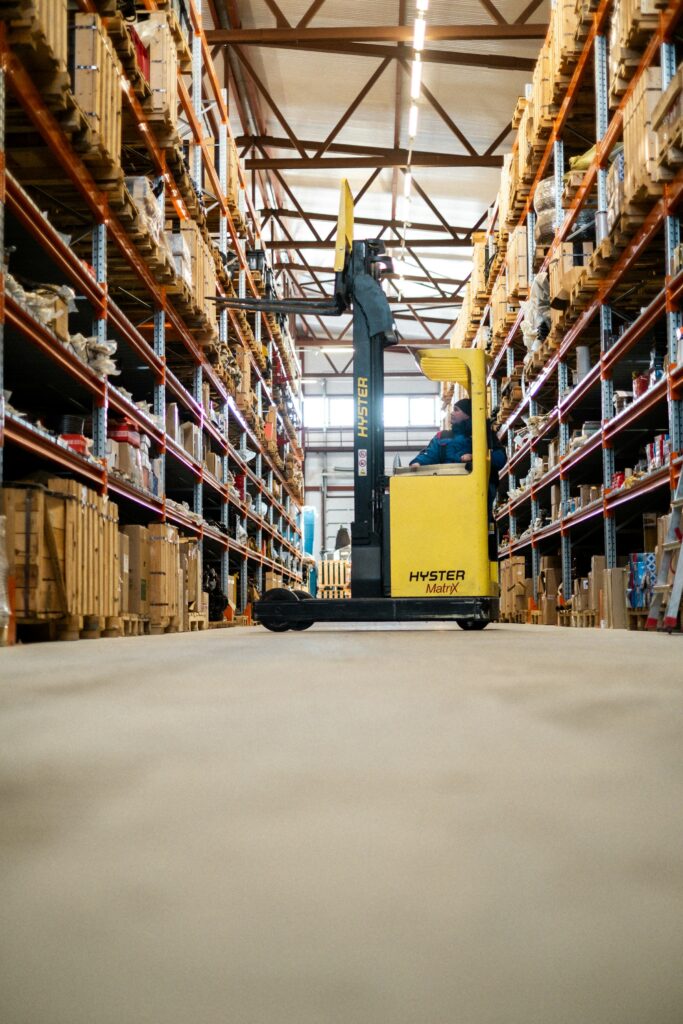

For Your MRO Warehouse or Storeroom

Maintaining an accurate and organized inventory is essential for any MRO warehouse. Without proper inventory management, the efficiency of your warehouse can be impacted significantly, resulting in disruption of operations, unnecessary expenses, and loss of productivity.

At Inventory Proline, we offer comprehensive inventory management services that can help you effectively control your warehouse and improve operational efficiency.

Helping You Implement the Best Practices for Effective Warehouse Inventory Control

Keeping track of all the items in an MRO warehouse requires a comprehensive approach to ensure accuracy and minimize losses due to errors or stock outs and other inefficient practices.

With efficient inventory management processes in place, as well as database accuracy and an optimal storeroom environment, warehouse managers can increase productivity while reducing costs associated with disorganization, data inaccuracies, ineffective processes, and more.

At Inventory Proline, we are experienced in helping clients create and implement effective warehouse strategies, unique to their specific needs, resulting in more effective warehouse inventory control. We will work closely with you to ensure your processes and systems are optimized, so you can maximize the efficiency of all your operations.

From the way you group products, build or enhance descriptions, and enter them into an inventory management system, to the way inventory flows through your warehouse to point of use, Inventory Proline will help you optimize your inventory management processes to maximize overall efficiency.

Working with a team of warehouse inventory specialists from Inventory Proline means you’ll benefit from:

- ROI within months of implementation

- Less downtime

- Reduced stress levels

- Spend avoidance and cost reductions

- Improved inventory turns

- Optimized inventory management, data, environment, and processes

What is MRO Inventory?

MRO inventory includes any item used to maintain, repair, or operate an organization’s equipment and facilities. These products can often be overlooked when it comes to efficient warehouse management but are critical to the success of your facility.

Common Challenges of MRO Warehouse Organization and Inventory Control

Organization and inventory control in a spare parts/MRO warehouse can be a complex process, and many warehouses struggle with common challenges such as:

- Data inaccuracies

- Inaccurate

- Inefficient or costly processes

- Limited insight into warehouse operations

- Lack of visibility in inventory management systems

- Ineffective use of space/layout

- Difficulty predicting stock requirements

- Unpredictability of lead time concerns

At Inventory Proline, we are experts in implementing inventory management solutions that can help alleviate these common challenges and set your facility up for success.

Why Effective Warehouse and Inventory Management Matters

Ensuring effective and efficient inventory management is essential for any MRO warehouse. Without sufficient inventory management in warehouse environments, you’re at risk for unexpected and unnecessary costs associated with downtime, lost productivity, and spot buys, as well as extra returns and duplicate orders and returns

With a well-managed spare parts inventory, you can:

Improve Efficiencies

Well-organized warehouses and inventory management systems can help to improve productivity by minimizing the time and effort required to locate or organize parts. Optimizing warehouse space usage, managing stock levels, monitoring stock movement, and reallocating slow-moving inventory can all help to improve inventory efficiencies.

Reduce Costs

Poorly-managed warehouses can be inefficient and costly. Implementing effective warehouse inventory control can help you optimize inventory levels for your space and needs, reduce storage and retrieval costs, improve supply chain efficiency, and reduce the risk of overstocking and stockouts.

Avoid Stockouts and Overstocking

Having accurate and up-to-date information on inventory levels is necessary to avoid stock outs, overstocking of parts, and downtime. Effective inventory management processes and procedures can help to ensure that the right parts are in stock when required, while also avoiding unnecessary expenses due to overstocking and extra storage costs.

Effective inventory management ensures that critical equipment spares, consumables, and maintenance products are available when necessary, reducing downtime; at the same time, accurate inventory management and warehouse organization also helps to control costs and avoid unnecessary overstocking and inventory inaccuracies.

Make Data-Informed Decisions

By understanding how to manage warehouse inventory for spare parts, you can make more informed buying and planning decisions in order to reduce costs and mitigate duplicate and wrong item orders.

An effective data-driven approach – achieved by having clean standardized data as well as tracking inventory levels, stock movement, lead time issues, asset utilization, and productivity – can provide valuable insights into larger trends and identify opportunities for continuous improvement.

Mitigate Risk and Increase Worker Safety

When products are not stored properly, the risk of physical hazards in the warehouse increases, threatening worker safety. Ineffective organization of MRO warehouse physical inventory can result in injury and incur OSHA fines, as well.

How Implementing an MRO Warehouse Inventory Environment Sets You Up For Success

With the right inventory environment, database, and processes set up, you can ensure that all of your spare parts warehouse inventory is exactly where you need it, when you need it.

Whether you require multiple warehouse inventory management solutions or a single solution to manage your MRO inventory storeroom, Inventory Proline can help you take full control of your operations.

Why You Need An Effective Inventory Environment

If you want to cut unnecessary costs, improve warehouse organization, and optimize your productivity, you need to know what you have in stock and where it is located.

With a reliable tracking system, you can ensure that all of your spare parts are stored correctly and can be easily retrieved when needed, reducing costs by optimizing inventory levels while also mitigating risk and improving worker safety. With a reliable inventory environment and data comes visibility into inventory levels, stock movements, asset utilization, and more, granting you data-driven insights into larger trends within the inventory you have.

Methods for Tracking Inventory in Warehouse Environments

Popular methods for tracking your spare parts inventory may include RFID, warehouse inventory labels (such as barcoding), visual tracking systems, vending solutions, routine inventory audits, and more.

Implementing whatever tracking methods make the most sense for your MRO inventory and facility will improve warehouse visibility and accessibility, as employees can quickly locate and retrieve parts with ease.

Inventory Proline can help with that implementation. Whether it is installing RFID, vending solutions, building/fixing/enhancing data to feed into your system, bar coding, or whatever your project requires, Inventory Proline can help get it up and running smoothly.

Benefits of Tracking Your MRO/OEM Warehouse Inventory In Real Time

Real-time inventory tracking enables you to increase operational efficiency, reduce costs, and get visibility into the current state of your MRO warehouse.

Benefits of real-time MRO warehouse optimization and inventory tracking include:

- Improved accuracy and visibility of inventory levels in the warehouse

- Increased operational efficiency by reducing time spent searching for parts

- Reduced costs from over-ordering and obsolete inventory

- Optimized storage space usage

- The ability to quickly identify and locate needed parts

For day-to-day operations as well as circumstances like moving warehouse inventory for reorganization, real-time data-driven insights and tracking enable you to stay on top of all stock movements, ensuring more accurate inventory numbers and better insights into your current supply needs.

Inventory Proline specializes in helping you efficiently manage spare parts inventory. Contact us today to learn more about how we can help you.

Essential Strategies for Effectively Managing Your MRO Warehouse Inventory

Warehouse inventory management is critical for any operation. With the right strategies and tools, you can reduce costs, optimize your storage space usage, and improve efficiency.

Inventory Proline can help you optimize the management of your spare parts inventory by implementing proven best practices in your warehouse or storeroom. You’ll experience the best results when you have an organized environment, standardized data that you can count on, and efficient processes that all drive inventory management excellence. Whether you need us to build it, fix it, or manage it, Inventory Proline can set you up for success.

Warehouse Layout Optimization & Design

Having an organized and optimized warehouse layout is essential for quickly locating items and reducing the amount of time spent searching. The design and layout of your spare parts warehouse or storeroom should be heavily influenced by a number of factors, including:

- Which items are fast or slow moving

- Which items are used together

- Lead time to replace items

- Which parts are critical for continued operation

- OSHA restrictions or requirements for storage

- Special handling requirements

From how to organize warehouse shelving to how to configure your warehouse aisles, Inventory Proline can help you design and optimize your spare parts warehouse layout for maximum efficiency.

Efficient Inventory Grouping and Location Tracking

Deciding how to organize and where to store your MRO/OEM parts can be a challenge, especially if you have a sizable inventory. Inventory Proline utilizes family grouping to make the storage of inventory in your warehouse more efficient and cost-effective.

By grouping “like items” together, a place for everything and everything in it’s place, we’ll enable you to easily find the items you need, track their movement, and know how reported inventory levels compare with actual inventory counts. Knowing exactly where every part is stored and organized makes it easier to quickly replenish your stock and reorder parts as necessary.

Reliable Data Management

Keeping accurate records of your MRO/OEM inventory is crucial for staying on top of stock levels, reporting, and compliance. Depending on your needs, Inventory Proline can build or optimize your MRO inventory database to better inform your inventory management system, ensuring that your data is more reliable and up-to-date.

Every mistake, delay, and inaccuracy adds up, costing you time and money. Prioritizing accurate record keeping for your inventory levels and needs can make a big difference in how efficiently your warehouse operates.